Products

1. High-Speed CT-AXI Solutions

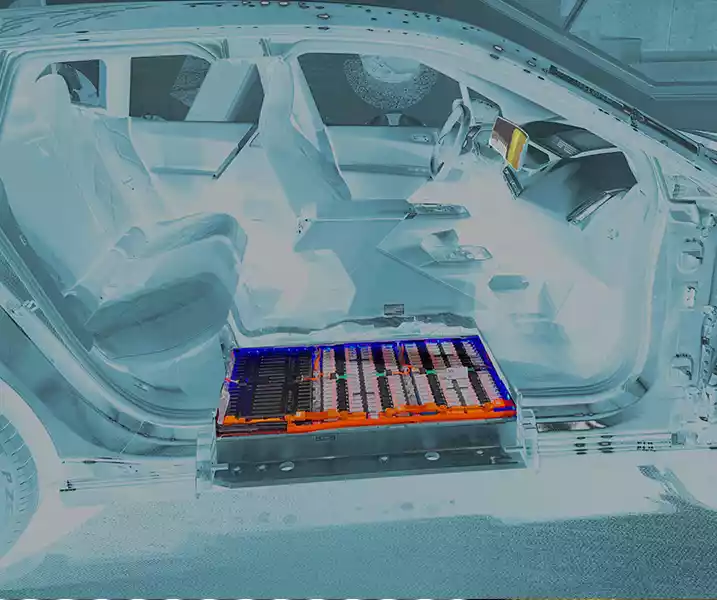

1.1 Automatic Battery Inspection

X2 Technologies offers high-speed CT-AXI with fully automatic handling and analysing solutions for a various range of different battery types and markets:

- Stacked battery inspection for phones/laptops

- Stacked and cylindric battery inspection for cars (automotive)

- Cylindric battery inspection for high-quality consumer products

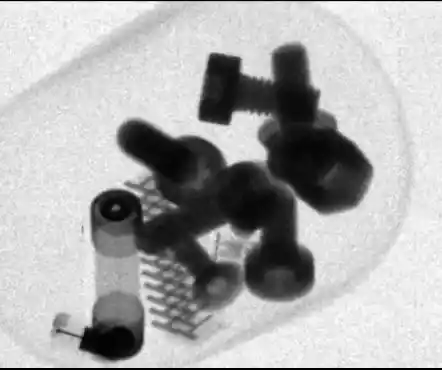

By using photon-counting detector’s with frame-rates up to 300fps and state of the art high-power μFocus X-RAY sources we guarantee CT-Cycle-times <5s with pixel (voxel) resolutions down to 20-30μ. Beside fully automatic slice position selections and a sophisticated measurement algorithm library we also offer for high volume production a dedicated AI/ML SW- tool packages for significant reduction of application support affords.

1.2 Large-Object CT Solutions

In this product platform we offer customized CT solutions for large objects up to 800x1000mm.

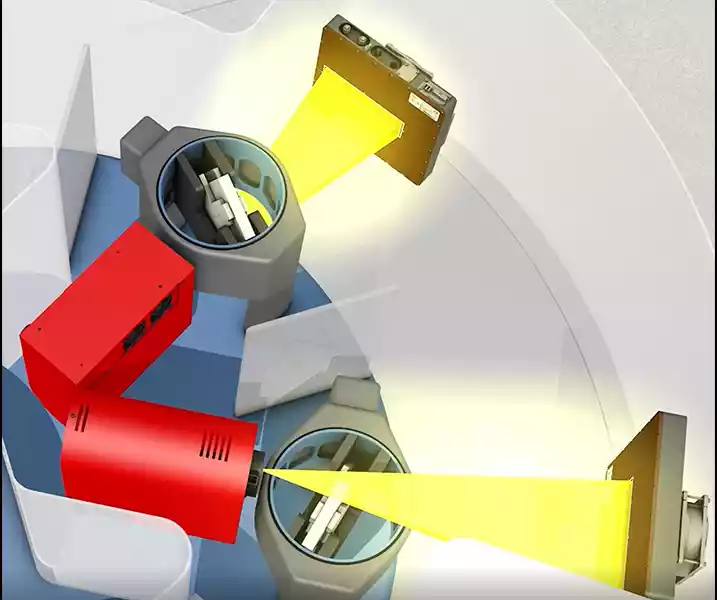

By using a DC photon-counting TDI Detector (available up to 1m length) in conjunction with a wide-beam tube we can reach FOV’s on the object up to 800mm length.

With our Spiral-CT Software (CT-Core with Siemens-Cera license) we can then generate volumes up to an object height of 1m or even longer as optional solution.

2. Super-High-Speed Real-Time Imaging

By using photon-counting detector technology high-speed real time imaging can be performed up to 5.000 fps. (frame/sec.). For high framerates the x-ray power is an important factor.

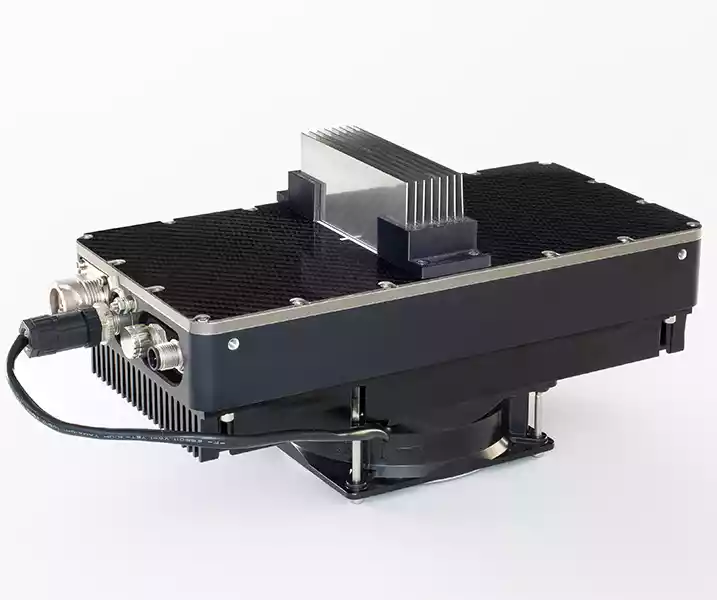

Complete X-Ray tray packages incl. the related real-time imaging process SW can be offered for various applications.

Typical available Hi-Speed solutions are:

2.1. Droptest

Hi-Speed Real-Time Droptest setups can be used for checking the robustness of high quality consumer products such as:

Smart-phones, laptops, watches, remote control’s, …

Typical Configurations:

Hi-Power Setup

High-Res. Setup

2.2. Crashtest

[coming soon]

3. Special NDT – Applications

3.1 In-Line Pipe-Inspection 2D/3D

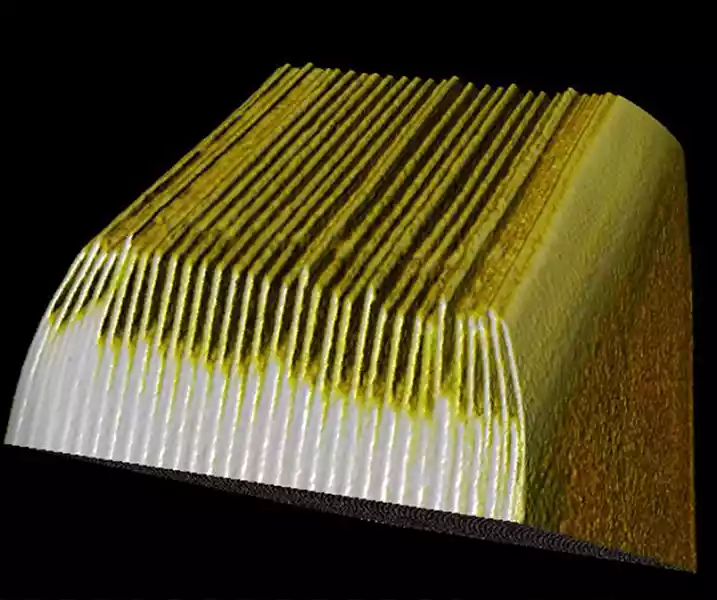

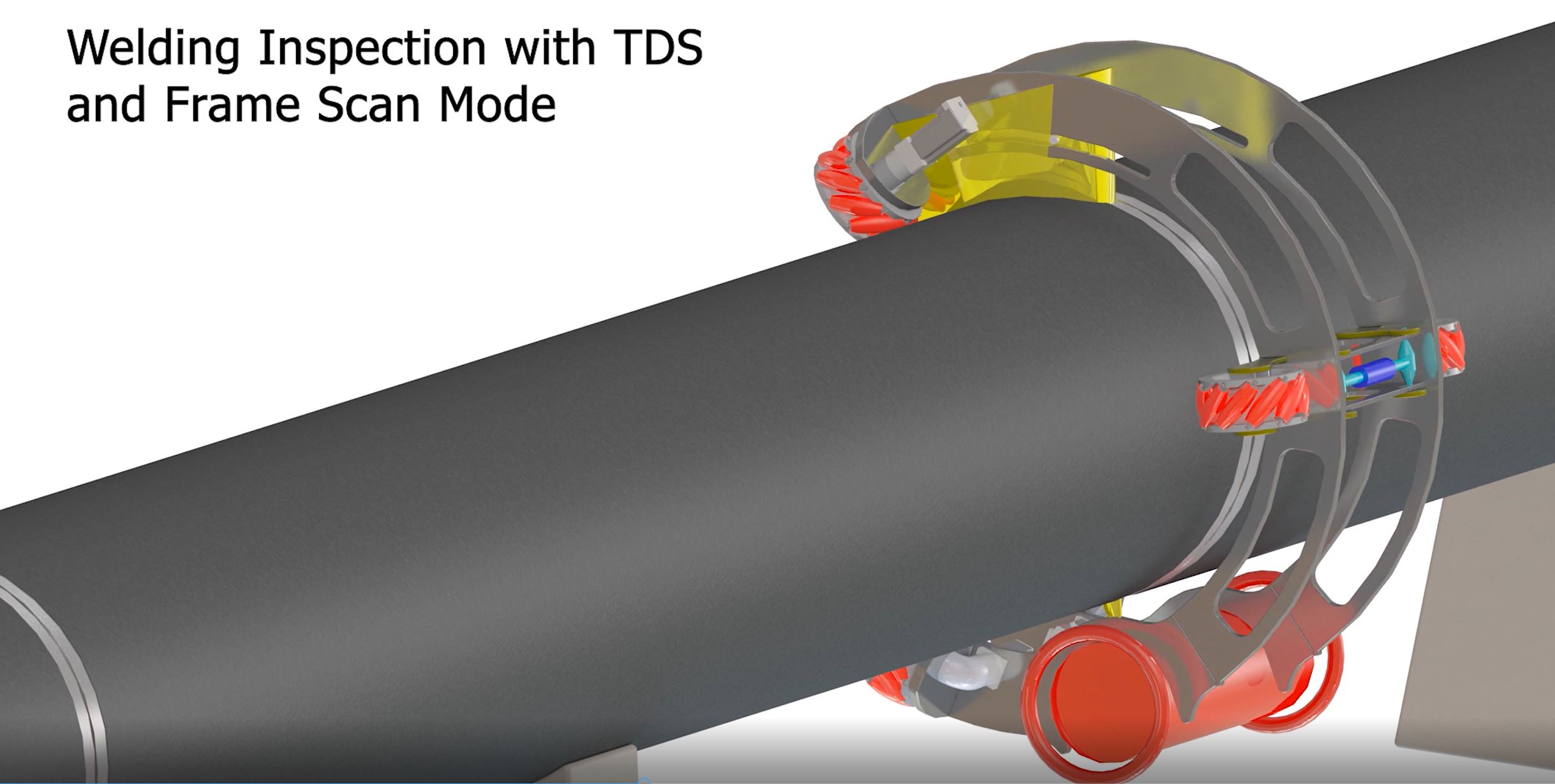

Innovative solutions for pipe inspection using photon-counting TDI technique in conjunction with rotational manipulation unit.

3.1.1. Welding-Inspection for steel-pipes

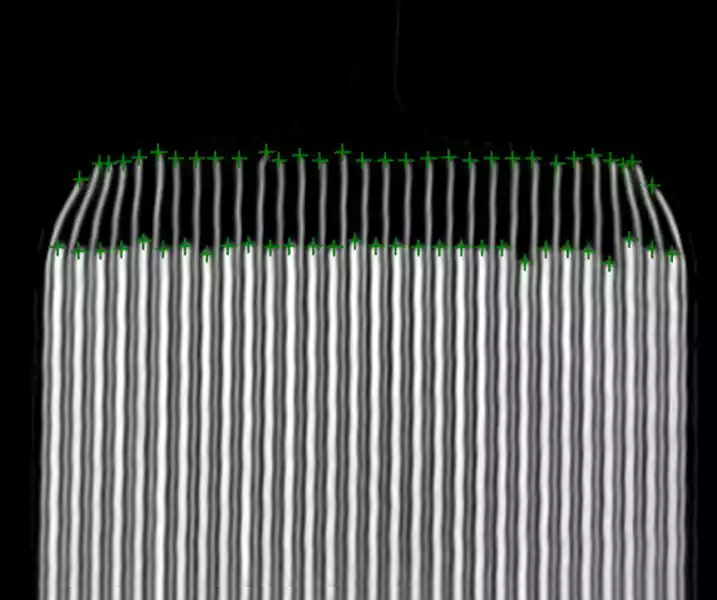

High-resolution scanning for welding inspection on heavy material’s using up to 256 pixel-lines.

3.1.2. Multi-Layer inspection of plastic pipes

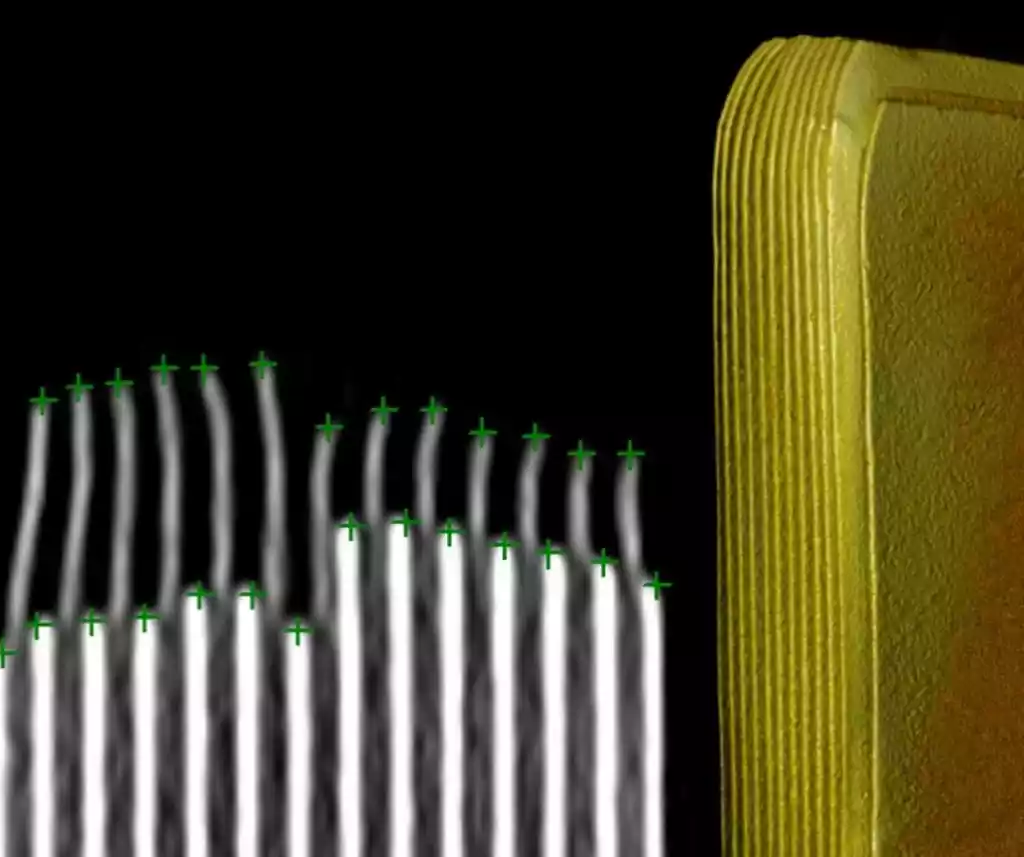

High resolution scanning for multi-layer structures with automatic inspection of wall-thickness, Delamination and material voiding

3.2 Hi-Energy X-RAY Imaging with Linac

Customized Hi-Energy X-Ray solutions are available for Hi-Power X-RAY tubes up to 600kV or Linear Accelerators up 6 MeV.