1. Photon Counting Technology

For High-Speed X-Ray applications we use photon counting detectors in our X-Ray systems. The key component in such detectors is the conversion material CdTe, which converts the X-rays into electrical signals, and a CMOS (ASIC) which transforms the electric signals into a data stream generated by the number of photons which has entered each pixel.

The higher efficiency of the CdTe converter material (versus traditional scintillators of charge integration techniques) provides higher sensitivities with almost zero dark current noise-levels. Due to the digital photon-counting technique on the sensor chip – image acquisition times of less than 1ms can be processed. Which results in frame rates (fps) > 1000 for real-time image sequences (i.ex. crash-tests) and CT-applications up to 500fps for CT-projection image acquisitioning.

The digital photon counting principle provides also the capability to setup multiple energy-thresholds in real-time, which can be very efficient used i.ex. for material separation. (Standard-Setup: Dual-Energy Mode)

Combined inspections-modes are available for dedicated application:

- TDI-Line scanning (Line-Scanner)

- Area/Frame-Mode (Flatpanel)

- Frame-Scan mode (Combination of both techniques)

2. CT-Reconstruction Techniques

| Available Scanning Methods | Stop for Grab/On-The Fly |

| Reconstruction Methods | FDK / SRM / Spiral-CT (new) |

| Automatic Geometrical Correction | via reference-object (CMP) via phantom based correction (new) |

| Scattering-Correction | via beam-stop array |

| Beam-hardening correction | |

| Ring-Artefact Reduction | via mathematical correction during reco via detector gray-level calibration |

| Field of View Extension | measurement range extension |

| Partial CT | via Truncate correction |

| CT-Volume optimization | Application specific Filter Algorithm Library |

3. AI / Machine-Learning Techniques

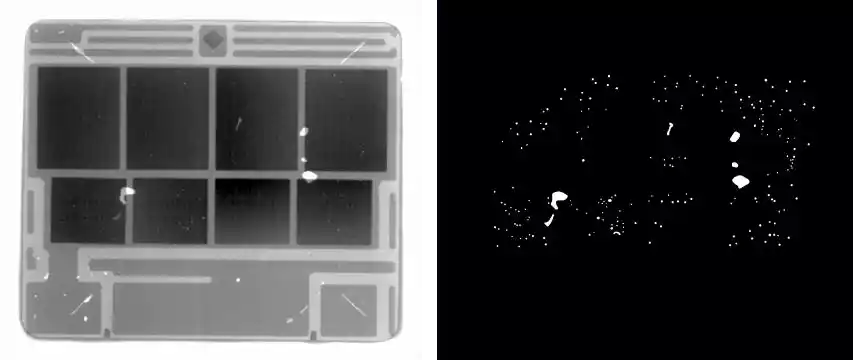

In combination with our inspection algorithm library we released now for dedicated applications also Deep-Learning Techniques based on Convolutional Neural Network.

To generate the trainings-models and prediction test-results we use a custom readaption of the TensorFlow UNet architecture.

3.1 Key-Elements of the X2-Tech Deep-Learning Workflow

3.2 Currently available Machine-Learning SW-Modules for the following applications

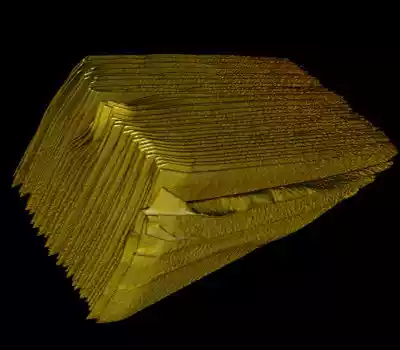

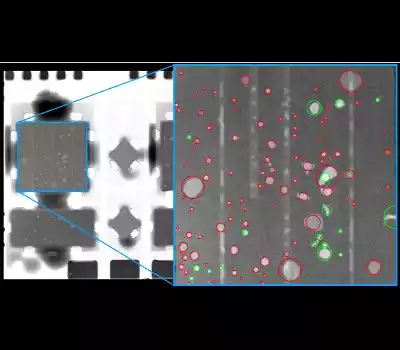

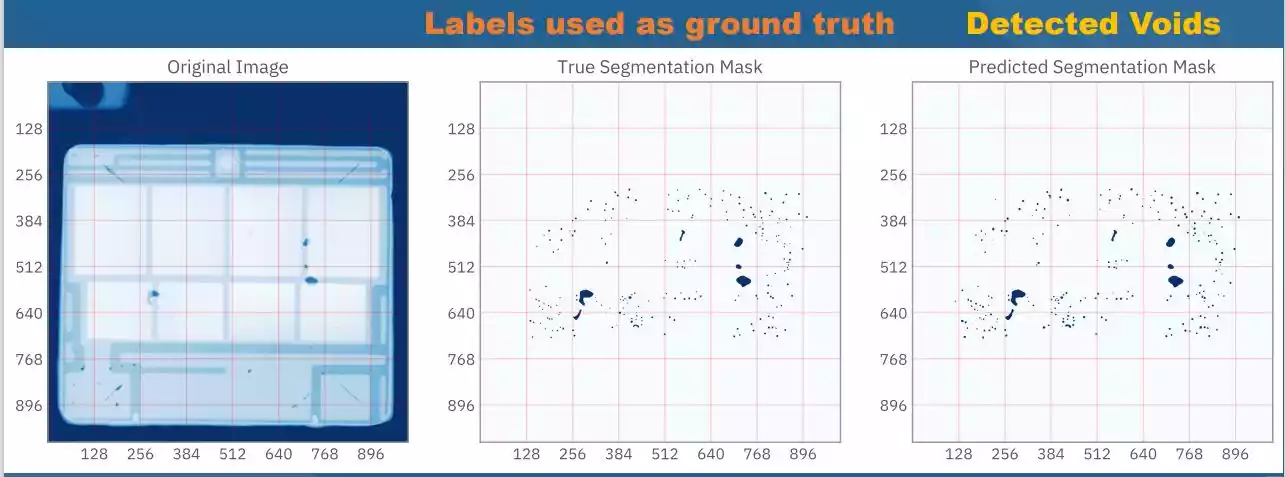

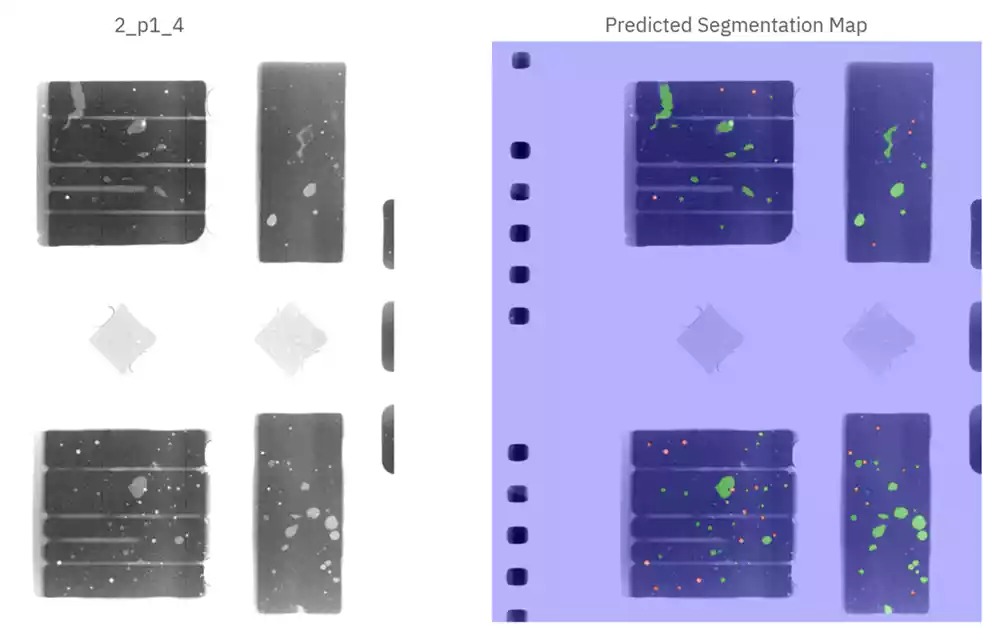

Void-Inspection for multi-layer components

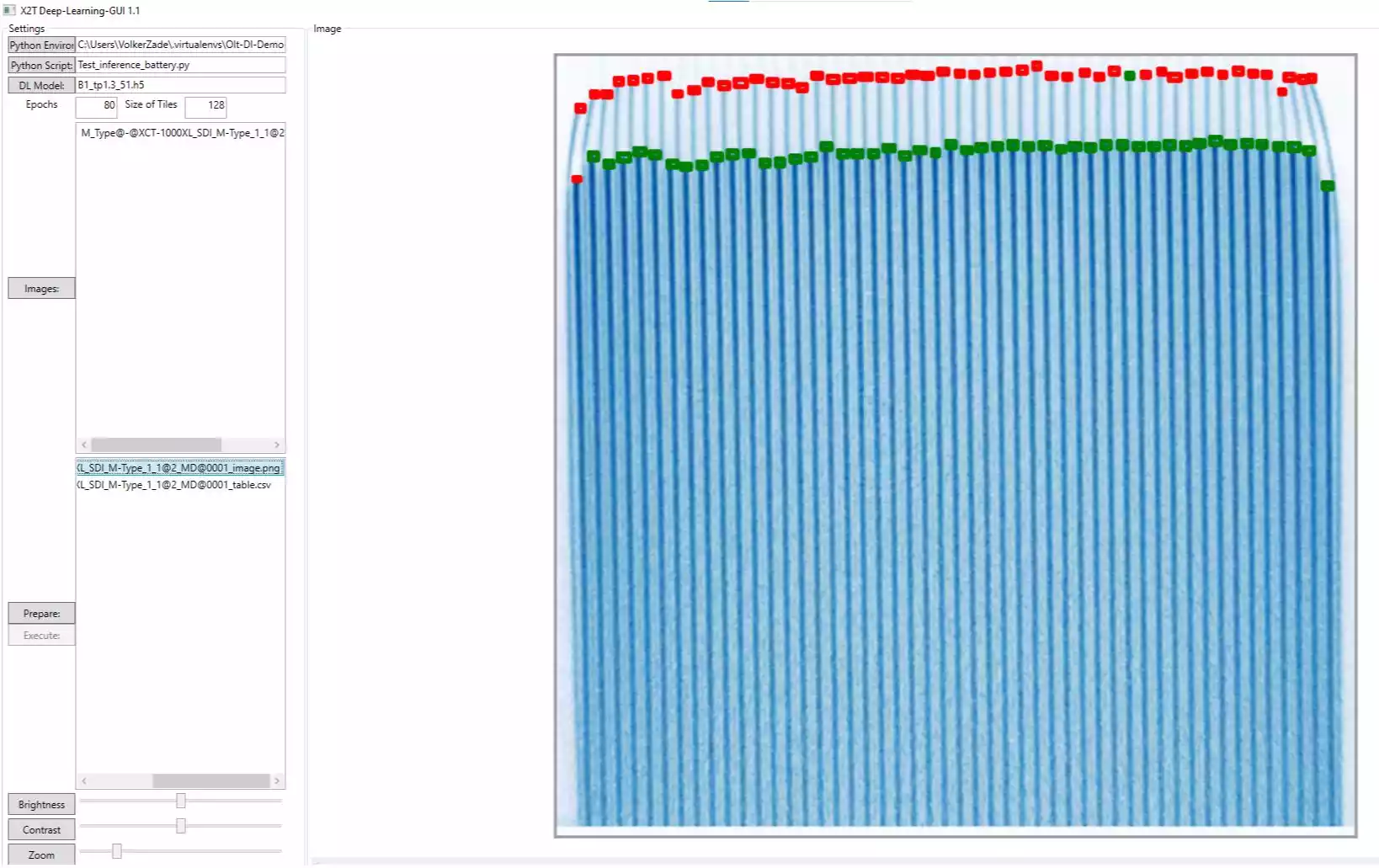

Anode/Cathode distance measurements for stacked batteries

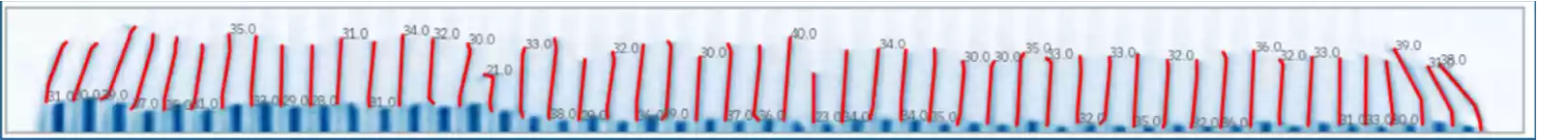

Anode-length measurements for stacked batteries

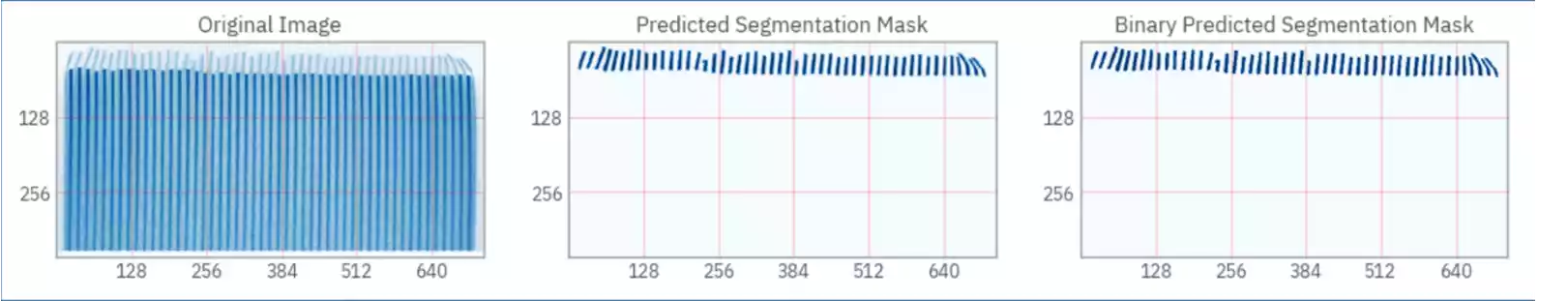

Machine-Learning Technique for detecting Anode-Length

Prediction Test-Result for Anode-Length measurement (in pixel-numbers)